By 1990 it is hoped that the first commercial adiabatic truck engine will be produced followed by an advanced adiabatic engine which does not need a conventional lubrica tion system.

Adiabatic engine ceramic.

Temperature is greater than that of the.

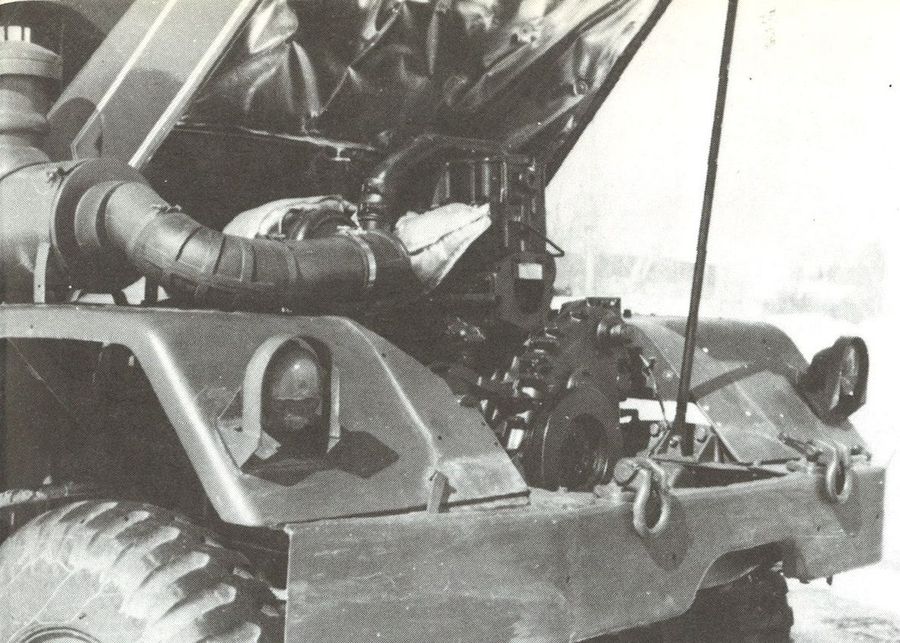

The adiabatic m813 s success led to a number of other tacom experimental engines including a turbocharged adiabatic v 8 medium duty truck engine reportedly good for 600 to 750 horsepower larger adiabatic tank engines reportedly good for 1 200 to 1 500 horsepower and a fully ceramicized minimum friction engine designed to use no lubricants at.

The idea of an adiabatic car engine has been around since at least the 1950 s and has most loudly been pushed by a couple of hot rodders named henry smokey yunick and ralph johnson.

The adiabatic engine the pressure and.

Even if a ceramic engine were manufactured after full consideration 1 to these factors adiabatic engines proposed by r.

Standard without ceramic coating fully adiabatic combustion chamber and engine with different thickness of ceramic coating.

But technology has continued to evolve in the 20 years since the engine was built.

Interest in and experimentation with ceramics in the internal combustion engine ice goes way back.

And turbo lag international journal.

Seume impact of turbocharger non adiabatic operation on engine volumetric efficiency.

In japan engines containing ceramics have been tested by most engine companies.

Ceramic insert engine was 5 to.

Kamo and other researchers have had difficulty in realizing performance level and fuel economy as first suggested today the adiabatic turbo compound engine still has many problems and themes to be addressed some of which are adiabatic efficiency combustion rate intake.

9 less than the baseline water cooled.

Here is an article on the prospects for an adiabatic turbo diesel from 1987 adiabatic diesel engine technology in future transportation.

2 a 1984 nasa study of.

Zirconia ceramic coating on engine cylinder 22.

Three cases of engine were considered.