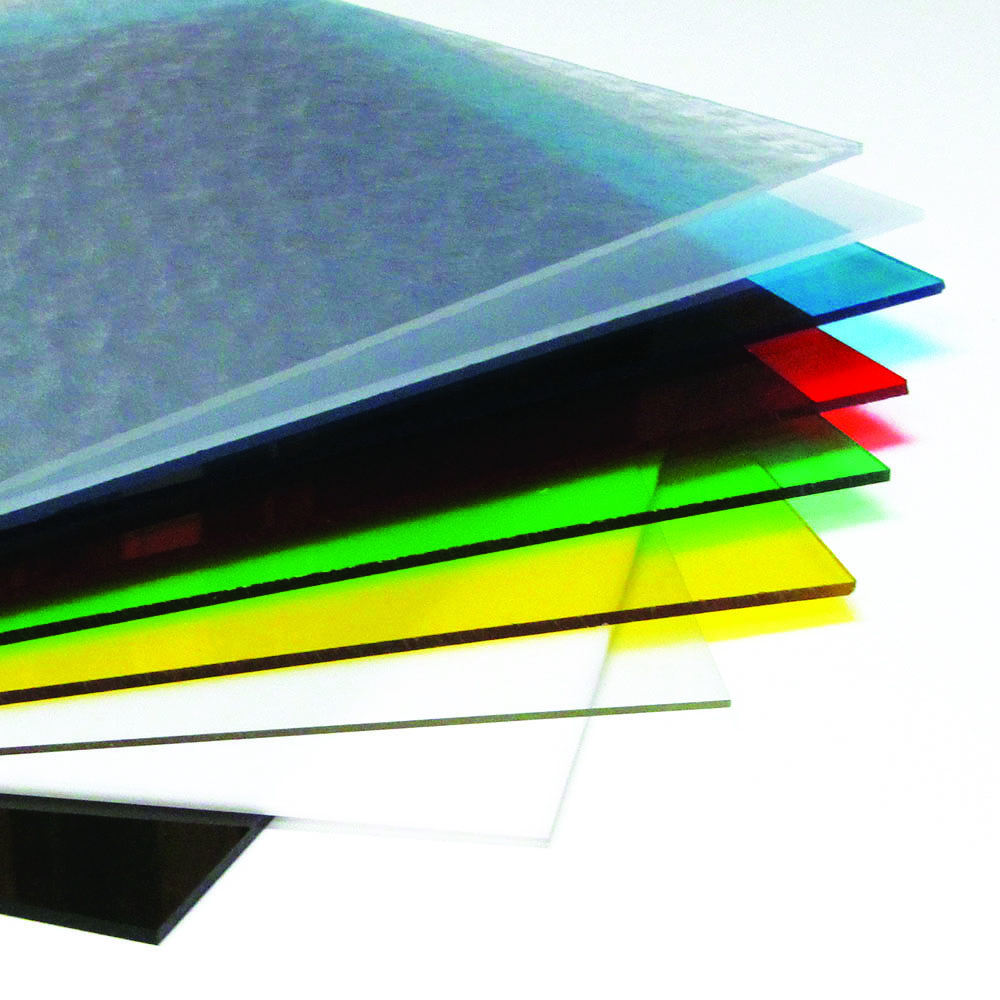

The physical properties of acrylic and plexiglass sheets acrylic plastic is a transparent thermoplastic homopolymer that is often colloquially referred to as plexiglass.

Acrylic sheets uses and properties.

Excellent dimensional stability and low mould shrinkage.

The clarity of clear acrylic sheets allow visitors to look around the wonders of the ocean.

It has superior weathering properties compared to many other transparent plastics.

While the form may be the same you will find that a clear polycarbonate sheet and a clear acrylic sheet are vastly different due to the physical and chemical properties of the plastic.

Acrylic sheet is easy to fabricate bonds well with adhesives and solvents and is easy to thermoform.

However acrylic sheeting can also be used at home.

Acrylic can be optically clear or cloudy as in the case of impact modified acrylics.

Rigid with good impact strength.

Acrylic is a transparent plastic material with outstanding strength stiffness and optical clarity.

Poly methyl methacrylate pmma also known as acrylic acrylic glass or plexiglass as well as by the trade names crylux plexiglas acrylite astariglas lucite perclax and perspex among several others see below is a transparent thermoplastic often used in sheet form as a lightweight or shatter resistant alternative to glass.

Excellent weatherability and resistance to sunlight.

Acrylic is one of the most durable materials and possesses water resistant properties.

Acrylic sheet has hundreds of different applications for commercial and residential construction.

Polycarbonate and acrylic share many of the same types of plastic sheeting options like clear colored mirrored and more.

Most acrylics are polymers of methyl methacrylate pmma.

They also play a large role in construction engineering outdoor displays and signage and even underwater camera lenses.

Because acrylic sheet is durable and shatter resistant it s great for upgrading or decorating your home.

Common uses include lenses acrylic nails paint security barriers medical devices lcd screens and furniture.

This plastic has unique properties that make it ideal for a variety of purposes ranging from basic household items to fiber optic cables that power the world.

Because of this quality acrylic is one of the most suitable materials to be used in making submarine windows.