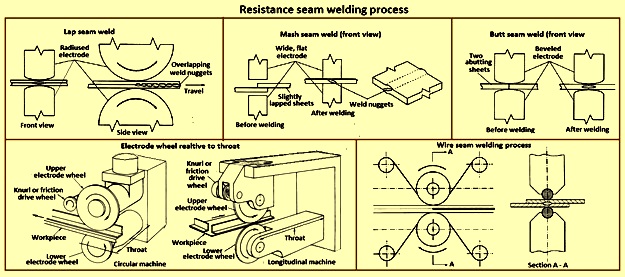

Gmaw gas metal arc welding and gtaw gas tungsten arc welding are two major welding processes in manufacturing industries 4 5 lots of research works have been done on the two arcs welding processes to accelerate the deposition much more new welding processes are invented especially in the areas of the high efficiency and high speed.

Ac pulsed gmaw improves sheet metal joining.

The ac pulse process reduces the heat input by focusing the energy away from the base plate and switching the polarity of the arc.

The process is an excellent alternative to constant voltage cv gmaw and may be a good option for companies looking to boost their.

Use new technology to improve first pass yield rates lower cycle times and reduce piece costs.

While not new to the industry pulsed gas metal arc welding sometimes referred to as gmaw p is still being adopted for the first time by many companies as a means to drive improvements in the welding operation.

The effects of complex waveforms of the process involving both the electrode positive ep and the electrode negative en pulse regions were investigated analytically.

The introduction of a negative polarity period assists in obtaining such characteristics due to an increase in the wire melting rate for this polarity.

Download citation ac pulsed gmaw improves sheet metal joining the innovative use of gas metal arc welding gmaw in improvement of quality and productivity of sheet metal joints was described.

New pulsed welding technology solves problems common to welding sheet metal.

Ac pulsed gas metal arc welding may be a good option for applications that require low heat input and high productivity.

The metal transfer in alternating current gas metal arc welding ac gmaw was analyzed in order to predict the drop size.

Say good bye to burn through.

Ac aluminum pulse gmaw brings features that cannot be realized with standard dc pulse mig welding.

Ueyama t tong h harada s ushio m 2000 improve sheet metal welding quality and productivity with ac pulsed mig welding system.